Free delivery for orders over €50, via Mondial Relay in mainland France

Our 100% French know-how is our quality signature. Within our workshop in Brittany, the couturières manufacture all our collections in recycled boat sail and our custom-made creations. They form one another and convey passion, know-how and precision. A bag takes between one and four hours to be made. Here are the main steps!

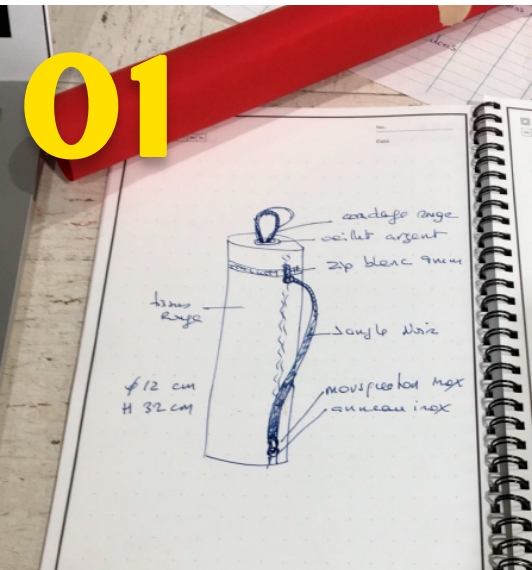

the sketches have long gone from an inspiration from Christine (to the very prolix creativity!), now from Pierre, our tailors, our customers, or a new habit of traveling, transporting. Pierre's first creation with his team: the backpack in technical veil of the teleworker!

From the sketch, Lucie develops a prototype of the piece. The prototype is often just at first stroke, and sometimes it must be done several times, in order to refine its cut, adjust its handles, the size of its eyelets,.

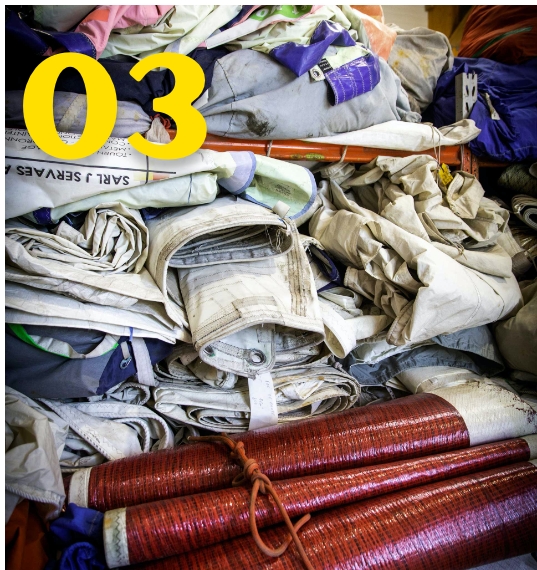

We collect the veils of racing stables, boaters and light sailings of individuals or nautical clubs. Every sailing gift is a blessing for us!

Every time, we are looking forward to discovering his story that shaped him and his asperities! We analyze the veil in its smallest corners, to check its quality, define which parts we can reuse or not, which defects can be masked by a detail of dressing like a number or strip, a seam, a piece of spi .

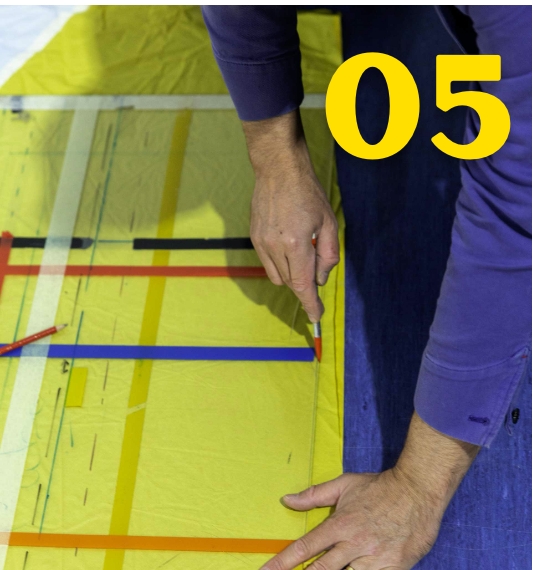

Once the veil is obsolete, we cut it off with our cutting templates. It is necessary from this stage to anticipate how the bag will be mounted: the seam of the veil, a grip of ris, an eyelet directs us and sometimes forces us. Transparent plexi plates with coloured cut patterns are used. Some are used for several models and color lines drawn on it could have been inspired by a painting by Mondrian! Cut edges must be clear and precise.

Once cut, we clean our pieces of veils, very simply, to the washing machine, with a natural product distributed by a local partner. All the marks of their history do not disappear, they say that the veils want to convey their message to us! Their superiority as a cream color or a less frank white will be the sign of a sail that sailed.

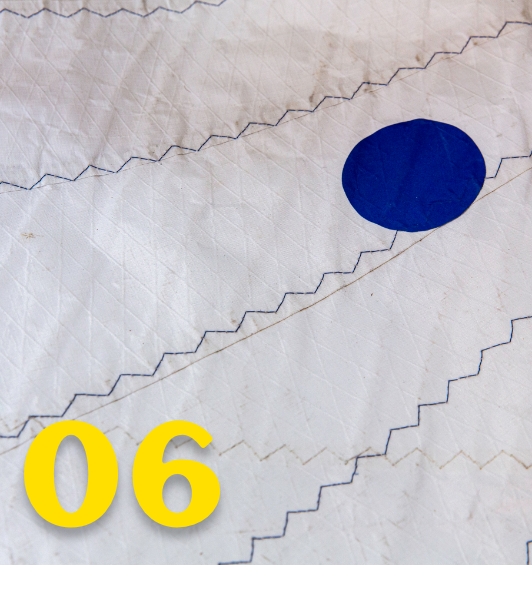

The canvas is guided by the hand of our seams to be sewn to the sewing machine. A special care is brought to the zig zag point, the traditional point of boat sails, which will give a particular aesthetic finish. The numbers, letters and insigna strips, cut first, are sewn on the canvas. The catch of ris and other details of sailors are added if they could not be taken from the original veil.

The laying of the eyelets is precise, careful, made using a traditional punching tool. Numbers, ris, and all exclusive details Vent de Voyage have created its inimitable style since its creation.

Other materials also prepare to be processed. The colors of the leather parts and the tips are carefully selected to coordinate with the colors of the canvas and its dressing.

We have 2 main types of handles: in the end with a hand stitched leather, or simply sewn and mounted braid with a spicy technique.

The seams of the leather handles are made using a coated thread with the help of an applelle. This coated thread is traditionally used in sailing to improve resistance in time.

Each bag Vent de Voyage wears a gauge pad. Originally, it is a stamp to certify during a regatta the official size of the veil. We diverted this stamp to include the manufacture number specific to this bag, the name of the model and its date of manufacture.